Vimatic ejectors are solid and built to satisfy costumers' requirements. In order to improve the performance, the ejectors can be individually designed. Each ejector is planned and assembled using the most suitable material that best fulfils the requested task. The characteristic parameters, such as pressures, back pressures, flow rate, aggressiveness of the circulating fluids, temperature, specific weights, viscosity, should be described in advance. Vimatic designs and assembles a big variety of ejectors.

PVC Vacuum Generators

BASIC CHARACTERISTICS

- Materials: PVC.

- Connections: entrance and intake 1/4" GAS F.F, exit 1/4 GAS F.M.

- Size: 69 x 41,2 x 26,5 mm.

Plastic cylindrical ejector

BASIC CHARACTERISTICS

- Materials: PVC - PP - PVDF - PE - PTFE ( other materials available on demand).

- Connections: threaded 1/4" GAS (can be customized).

- Size: standard body Ø40, variable length.

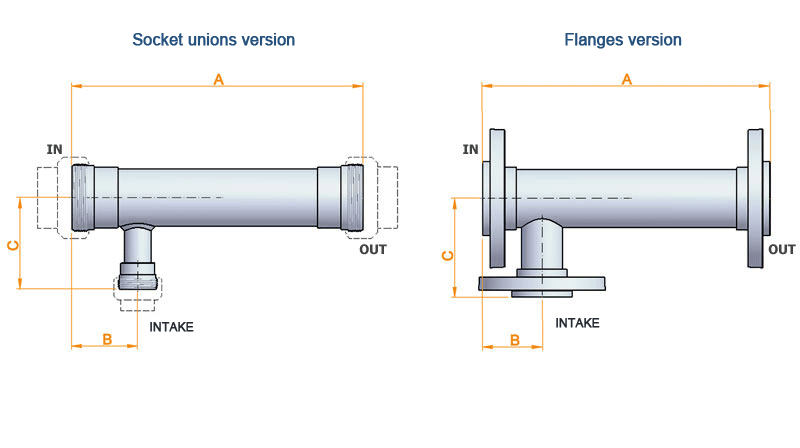

Plastic ejectors series with pipe unions

Plastic ejectors series with flanges

BASIC CHARACTERISTICS

- Materials: PVC - PP - PVDF - PE - PTFE (other materials available on demand).

- Connections: with pipe unions (up to ND 65) - with flanges (for bigger diameters). Special connections on demand.

- Gaskets: NBR or EPDM (other materials available on demand.

- Size: approximate as in the chart (see scheme.

|

CODE (standard) |

ND | SOCKET UNIONS MODELS |

FLANGES MODELS |

||||||||

| A | B | C | IN/OUT | INTAKE | A | B | C | IN/OUT | INTAKE | ||

| E.304.xxx |

15

|

125

|

38

|

42

|

ND15

|

3/8"-1/2"-3/4"

|

/ | / | / | / | / |

| E.305.xxx |

20

|

180

|

52 | 38 |

ND20

|

ND15

|

180 | 52 | 75 | ND20 | ND15 |

| E.306.xxx |

25

|

225

|

45

|

45

|

ND25

|

ND20

|

225 | 53 | 88 | ND25 | ND20 |

| E.307.xxx |

32

|

250

|

62

|

46

|

ND32

|

ND20

|

250 | 62 | 101 | ND32 | ND20 |

| E.308.xxx |

40

|

310

|

67

|

45

|

ND40

|

ND20

|

310 | 68 | 100 | ND40 | ND20 |

| E.309.xxx |

50

|

351

|

80 |

58

|

ND50

|

ND25

|

348 | 72 | 119 | ND50 | ND25 |

| E.310.xxx |

65

|

523 |

100

|

72

|

ND65

|

ND32

|

550 | 112 | 112 | ND50/65 | ND50 |

| E.311.xxx |

80

|

/

|

/

|

/

|

/

|

/

|

610 | 87 | 135 | ND80 | ND32 |

| E.312.xxx |

100

|

/

|

/

|

/

|

/

|

/

|

846 | 125 | 146 | ND100 | ND65 |

| E.313.xxx |

125

|

/

|

/

|

/

|

/

|

/

|

1122 | 225 | 150 | ND125 | ND65 |

| E.314.xxx |

150

|

/

|

/

|

/

|

/

|

/

|

1187 | 289 | 207 | ND150 | ND100 |

| E.315.xxx |

200

|

/

|

/

|

/

|

/

|

/

|

1738 | 315 | 200 | ND200 | ND50-110 |

Metal ejectors

BASIC CHARACTERISTICS

- Materials: Stainless Steel 304/L-316/L (other materials available on demand).

- Connections: threaded, CLAMP, DIN, flanges UNI or ANSI (other materials available on demand).

- Gaskets: NBR or EPDM (other materials available on demand).

- Size: completely customizable.

- Q = motive fluid's flow rate (e.g. water; this information is used to define the ejector's nominal diameter).

- P = motive fluid pressure.

- Suction = amount of intaken fluid (in case the fluid is not similar to water its nature should be defined: e.g. chemical formula, specific weight or viscosity) - height from which you want to intake it.

- O.p. = back pressure, i.e. the pressure situated at the ejector's exit. This information is very important since it conditions the ejector efficiency and therefore its intake capacity.

We want to stress the fact that an appropriate sized ejector can overcome significant pressures (e.g. a pressurized tank or a high located tank). Moreover, the knowledge of the length of the tubes connected to the ejector and the height from which the fluid has to be sucked, can make the calculations easier.

Technical patterns are available in the DOWNLOAD area. Please register to see them.